LABORATORY DETAILS

| SR.NO. | NAME OF LABORATORY | LAB. AREA (Sq. Mtr) | INVESTMENT (Rs.) |

|---|---|---|---|

| 1 | FLUID MECHANICS | 160 | 1,88,512/- |

| 2 | BASIC MECHANICAL ENGINEERING | 160 | 29,138/- |

| 3 | APPLIED THERMODYNAMICS | 70 | 3,09,047/- |

| 4 | CAD/CAM | 70 | 18,39,991/- |

| 5 | THEORY OF MACHINES I | 70 | 1,06,283/- |

| 6 | FLUID MECHINERY AND FLUID POWER | 160 | 6,84,801/- |

| 7 | METALLURGY | 160 | 2,12,988/- |

| 8 | METROLOGY & MECHANICAL MEASUREMENT | 70 | 3,09,274/- |

| 9 | THEORY OF MACHINES II | 70 | 1,46,630/- |

| 10 | HEAT AND MASS TRANSFER | 70 | 2,08,069/- |

| 11 | INTERNAL COMBUSTION ENGINES | 77 | 10,68,750/- |

| 12 | EXPERIMENTAL STRESS ANALYSIS | 70 | 1,99,420/- |

| 13 | MANUFACTURING PROCESSES | 160 | 1,000,24/- |

| 14 | AUTOMOBILE ENGINEERING | 77 | 1,88,859/- |

| 15 | REFRIGERATION AND AIR CONDITIONING | 70 | 4,23,281/- |

| 16 | WORKSHOP DEPARTMENT | 1330 | 33,55,942/- |

| TOTAL | 93,71,007/- | ||

Fluid Mechanics

The Fluid Mechanics laboratory is designed to examine the properties of fluids and to conduct experiments involving both incompressible and compressible flow

Major Instruments/ Machines :

- Losses in pipe fitting apparatus

- Losses in pipe friction apparatus

- Losses in pipe friction apparatus

- Verification of Bernoulli’s theorem

- Flow over notches apparatus

- Flow measurement by venturi meter and orifice meter

Basic Mechanical Engineering

The laboratory is well-equipped and enables students to understand the basic construction of two stroke and four stroke diesel and petrol engine. The laboratory also consists of different types of gear arrangements, Model of Hydropower plant etc.

Major Instruments/ Machines :

- Model of Gas Turbine

- Model of Hydro Power Plant

- Cut Section Model of 2 Stroke petrol Engine

- Cut Section Model of 4 Stroke Petrol Engine

- Cut section Model of 4 Stroke Diesel Engine

- Model of Spur Gear

- Model of Bevel Gear

- Model of Spiral Gear

- Model of Helical Gear

- Model of Worm Gear

Applied Thermodynamics

The Applied Thermodynamics laboratory consist of different Prototype models of Boilers, Grease penetration test, Bob calorimeter etc.

Major Instruments/ Machines :

- Grease penetrometer

- Dropping point apparatus

- Carbon residue apparatus

- Cloud & Pour point of a lubricant apparatus

- Redwood viscometer apparatus

- Aniline point apparatus

- Flash & Fire point apparatus

- Lever Safety Valve

- Spring loaded safety valve

- Dead Weight Safety valve apparatus

- Water level indicator apparatus

- Steam stop valve apparatus

- Feed check valve apparatus

- Steam injector apparatus

- Pressure gauge apparatus

- Blow off cock apparatus

- Bomb calorimeter apparatus

- Reciprocating air compressor apparatus

- Babcock & Wilcox apparatus

- Cochran Boiler apparatus

- Lancashire Boiler apparatus

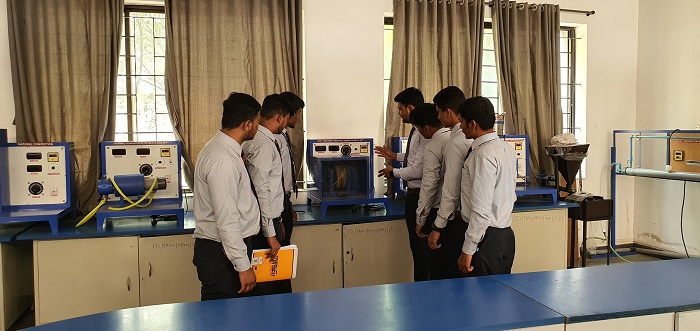

Heat & Mass Transfer

Name of Laboratory In charge : Prof. K.M. Dudhal M.Tech. Structural Engineering.

Name of Laboratory Assistant : Prof. K.M. Dudhal M.Tech. Structural Engineering.

The Hydraulics Lab area in 70.00 sq.meters. There is sufficient space for every student to work in the laboratory about 20 students can do practical at a glance. Timber cupboards are provided for keeping the Materials and weights required to perform experiments.

Other facilities include electric supply on wall, drainage, fans and tube lights are provided. so that practical’s can be performed easily and in working atmosphere. Laboratories are kept clean and well maintained regularly. Each laboratory is under the supervision of lecturer in-charge appointed by principal every year.

Major Instruments/ Machines :

- 1) Turbines with all Charts

- 2) Tilting flume (4 m length in Hydraulic open channel)

- 3) Centrifugal pump test ring closed circuit type(2HP) with charts

- 4) Electrical analogy apparatus

- 5) Pizometer, manometer, pressure gauge, hook or point gauge test set up

- 6) Impact of jet apparatus

- 7) Flow measurement by venturimeter and orifice meter

- 8) Flow throw orifice and mouthpiece apparatus

- 9) Bernoulli’s test set up

- 10) Reynolds Apparatus Type (a)

- 11) Calibration of V notch/ rectangular notch

- 12) Ship model (meta-centric heights apparatus)

- 13) Losses in pipe fitting apparatus

- 14) Losses in pipe friction apparatus

Fluid Machinery And Fluid Power

The Fluid Machinery and Fluid Power laboratory is used to get real time experience of Hydraulic and Pneumatic trainer kit, this lab also having working models of Different turbines

Major Instruments/ Machines :

- Pelton wheel Turbine Test Rig.

- Francis Turbine Test Rig.

- Centrifugal Pump Test Rig.

- Gear Pump Test Rig.

- Hydraulic Trainer Kit

- Pneumatic Trainer Kit

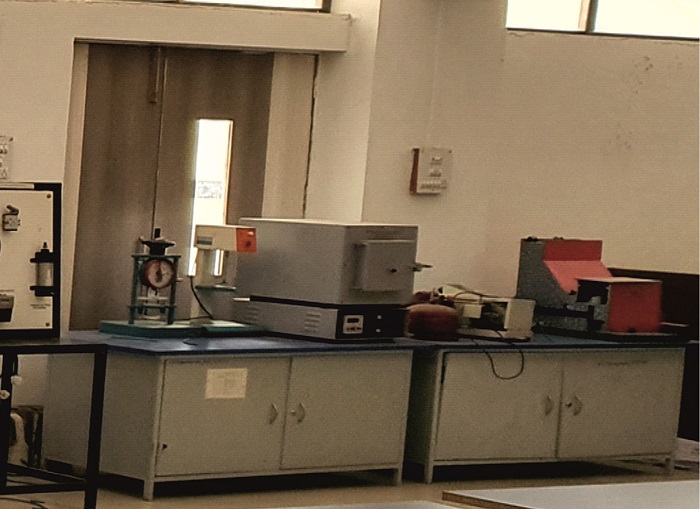

Metallurgy & Mechanical Measurement

The Metallurgical Laboratory contains various ferrous and non-ferrous specimens, specimen preparation machines, material microstructure analysis using microscope. The main objective of lab is that students should able to prepare samples of different materials for metallography & study microstructure of various metals.

Major Instruments/ Machines :

- Trinocular Microscope With Computerized Attachment

- Muffle Furnace

- Standard Metallurgical Microstructure Set

- Abrasive Belt Grinder

- Double Disk Polishing Machine

- Mechanical Comparator

- Vernier Caliper Digital 150mm

- Vernier Caliper 300mm

- Micrometer 25-50

- Slip Gauges Set (83 No’s)

- Bevel Protractor

- Thread Pitch Gauges

- Tempreture Measurement Module -Thermocouple

- Tempreture Measurement Module- Thermister

- Tempreture Measurement Module- R.T.D

- Dead Weight Pressure Gauge Tester

- Flow Measurement By Rotameter

- Vibration Measurement

- Strain Gauge

- Stoboscope

- Tachometer

- Sound Measurement Module

Theory Of Machines

The most objective of Theory of Machines laboratory is to impart sensible information on style and analysis of mechanisms for the desired variety of motion .In this Lab study of relative motion between the various parts of a machine, and forces which act on them.

Major Instruments/ Machines :

- Motorised Gyroscope

- Generation of Gear Tooth Profile

- Static And Dynamic Balancing apparatus

Internal Combustion Engines

Internal Combustion Engine Laboratory is a well-equipped laboratory which provides ideas on practice of handling IC engines and measuring the performance parameters. This laboratory is scheduled for 6th semester Mechanical engineering students. Some additional engine cut models of IC Engines are there which helps the students to enhance their knowledge.

Major Instruments/ Machines :

- 3 Cylinder ,4Stroke petrol engine with hydraulic dynamometer

- Computerized VCR engine set up ,Single Cylinder,4Stroke Engine

Automobile Engineering

The lab is well-equipped and enables students to understand the fundamentals of Automotive Engineering which includes basic structure, body style, power plant.

Major Instruments/ Machines :

- Cut section model of four-wheeler Engine.

- Working model of Two-Wheeler Engine Two Stroke.

- Working model of Two-Wheeler Engine Four Stroke.

- Working model of diaphragm spring type clutch.

- Working model of synchromesh gearbox

- Working model of differential.

- Working model of steering gearbox rack and pinion.

- Working model of rigid axle suspension.

- Working model of hydraulic braking system.

- Battery and charging system.

- Multiplate clutch.

- Constant mesh gearbox.

Refrigeration And Air Conditioning

Refrigeration and air-conditioning deals with the techniques to control the environments of the living and non-living subjects and thus provide them comforts to enable them to perform better and have longer lives.

Major Instruments/ Machines :

- Refrigeration Test Rig

- Air-conditioning Test Rig

- Ice -Plant test Rig

- Mechanical Heat pump Test Rig

- Vapour absorption Test Rig

Workshop

Our workshop is well equipped with all traditional and non-traditional machines and their accessories with every measuring instrument. As we operate in both Polytechnic as well as Engineering shift we cater to the students’ requirements. We have various sections wiz Machine Shop, Carpentry Shop. Fitting, Sheet Metal, Smithy, Plumbing and Wielding section. All the above mentioned sections are utilized for the practical work of FE (All Branches) as well as TE (Mechanical) for Degree and for Polytechnic.

Major Instruments/ Machines :

- Lathe Machine (light duty) with three Jaw

- Medium Duty Lathe Machine with three Jaw Chuck

- All Geared Lathe Machine

- Radial Drilling Machine

- Verticle Milling Machine

- Surface Grinding Machine

- Shaper Machine